I own the KLAudio cleaner. Yes, they have gone out of business but I believe will continue to service existing units if needed. While I think the A Deske is effective, one of the reasons I did not buy it was specifically for the moving parts referenced here in the form of the brushes and the need for a surfactant. With good reason the pricing of replacement parts is very high as detailed by Michael.

What's the Difference Between These Two Mini-Rollers? (Actually More Than I Thought!!!!!!)

And the word "key" is a play on words. Yesterday, after successfully using the paint rollers in place of the costly ones from Audio Desk I wrote the story below. Today when I tried using the machine the rollers did not reliably spin despite being seated properly. The difference, as I just discovered, is a tiny ridge in the plastic insert that "spring loads" the roller's plastic innards to the Audio Desk shaft. Without it the fit is too loose and the microfiber roller can lift up once the water level rises, and then not spin.

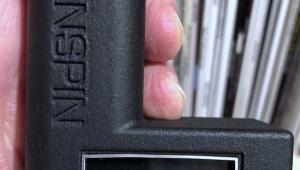

So, while it's clear that the hole in the bottom of the roller has been drilled "after the fact", I'm not sure of the origin of the ridge you can see in this photo, nor can I think of a way to created one inside the plastic shaft. Without it, the fit is too loose:

So ignore everything below and for now it's spend $99.95, but that's an awfully costly ridge!

My apologies to all!

The other difference is the price: each roller in the Audio Desk $100 set of 4 costs $25.00. The rollers from Home Despot cost $2.64. Yes, you must drill the tiny hole yourself, but otherwise they appear to be identical and they work identically as well.

No wonder when I visit Audio Desk owners I more often than not find dirty, brown, rollers! I understand that someone has to drill the holes and the distributors like The Cable Company need a mark up to sell these things to you, but come on! I bought a 12 pack at Home Despot for $31.68 and took about five minutes to carefully drill out the holes.

I used an 1/8th inch drill bit and then gently reamed it slightly out. You must drill carefully and parallel to the roller (not at an angle) or the roller will wobble when it spins. It's also important to be sure that the hole is "flat" for the same reason.

The rollers look, feel and work identically to the $99.95 set of four because they are essentially the same thing! They are Premier brand 4"x1/4" NAP Mini Rollers, Home Despot store SKU #1002084729.

I bought a box of 12 for $31.68 and you can be sure I will be replacing the rollers more frequently!

P.S.: I don't think the colored stripe on the $2.64 roller will "come off" and pollute the record if that's what you're thinking. These are, after all, paint rollers!

I like the Audio Desk machine and use it routinely along with the Kirmuss machine for "restoration" purposes, but there's no reason for the rollers to cost $99.95, nor for that matter for the mini-bottle of surfactant/detergent to cost $25! But that's more difficult to analyze and deconstruct!

- Log in or register to post comments

Mine won’t do that without the surfactant,

As a KLaudio owner, the lack of a surfactant is easily overcome by a prior wet cleaning using an enzyme agent on a vacuum type RCM. I think this is a highly desirable first step in record cleaning. Putting dirty or even heavily soiled LPs in an ultrasonic cleaner can lead to problems later. Anecdotally it seems that some KLaudio customers experienced problems with their units due to clogged filters/pumps causing them to malfunction and not operate properly. I experienced this myself after a number of years and now regularly clean the filter screen when I change the water. You would be surprised at how much debris (airborne dust post wet cleaning?) accumulates on the screen even when cleaning pretty much pristine records on the KLaudio. The same rationale I think would apply to the Audiodesk? A thorough wet pre-clean would keep the rollers cleaner for a longer period too, I imagine. At the factory prices quoted, I can readily understand why users are slow to order new sets!

I hope KLaudio reconsiders its recent decision to discontinue its RCM. It is a very good product and has unequivocally enhanced my enjoyment of vinyl records with zero surface noise, just music.

Pre Clean step with surfactant is key. I use a Spin Clean to remove most debris, and emulsify surface contaminants. I use "rushton's" formula in my DIY US system to very good effect. I end with a vac dry.

Seems simple enough to make. Or you could pull off that piece of plastic and find a center punch that fits the existing hole and use it to locate the hole. Not sure what size the hole is, but here's an entire set for $19. One of them should fit. If you know the size of the hole, you might be able to buy a single punch. But, $19 isn't a lot of money. These things are handy, so a set is nice to have.

https://www.amazon.com/dp/B07PNS2ZSY

I would mark the hole using the center punch to make a dimple at the right location. Use a smaller drill bit to make the through hole through the dimple. A smaller drill bit won't walk out the dimple. Then use the correct size bit to finish off the hole. A larger bit will find center on the smaller hole.

I raised the pricing of rollers,filters and wipers with the U.k. distributor a couple of years ago. I was advised these are specialist items and reasonably priced, Hmmm...

I have been popping both the rollers and the filters in the washing machine and they come out clean,fresh and sweet smelling,just like my smalls.....

As DIY is not my forté I’ll excuse myself from drilling etc.

BTW I have found the newer black wipers to be considerably more effective and durable than the older white ones. The distributor didn’t know whether they would fit my early Pro machine or be any better but an email direct to AudioDeske confirmed they would fit and should be better. Aren’t distributors supposed to know this stuff?

Keep up the good work Michael.

Alastair in London.

...for us other owners of AudioDesks.

Quite a few owners have reported difficulties in replacing the white wipers. The solution that I have seen involves coating the edge that mates with the groove in the machine with a little washing up liquid so that it acts as a lubricant. Was this kind of thing necessary with the black replacements?

As for popping the filters and rollers in the washing machine what temperature did you select ( bearing in mind that the filters are plastic foam)? Also when washing towels the detergent is difficult to rinse away thoroughly ( a main reason why soft new towels end up hard and almost scraping the skin off your back after a few washes:-). Just add another rinse cycle and see how much additional foam emerges! So did you use detergent or just run a programme without adding any?

Thanks.

Yes the washing up liquid on the end of the wiper to be inserted helped. It was still a bit of a process to get the new wipers fully in. Too much tugging and they break.As I found out.....

I just throw the rollers and filters into a normal 30 C wish with a normal white clothes wash and Ecover non- bio powder.

I’m undoubtedly not as dedicated as many of the contributors and no doubt some will throw their hands up in horror at the very thought of what I am suggesting. However I can discern no change in the roller fabric look,feel or effectiveness after washing and I haven’t noticed any issues with detergent foaming in the Audiodeske. However an extra rinse does sound like a good plan.

I always pre-clean second hand records on my old but trusted Clearaudio Matrix before an AudioDeske clean.New records go straight into the Audiodeske.

The first question would be: “If the AudioDesk is an ultrasonic cleaner, then why the brushes in the first place”? What are they for? Stabilization? Surfactant spreading? Part of the drying cycle?

One reason the parts are so expensive is because the logic (in the manufacture’s mind) follows that if one can afford $5K for the machine, then one can afford $100 for a part. (In my personal view, this is faulty logic from the start, but I’m not the one selling or using these things).

Surfactants are not just for emulsifying oil and grease; in fact, it depends on the composition of the surfactant as to the range of function. Primarily, surfactants are compounds that lower the surface tension (or interfacial tension) between two liquids, between a gas and a liquid, or between a liquid and a solid. Surfactants may act as detergents, wetting agents, emulsifiers, foaming agents (this is what you see happening with the Kirmuss surfactant when you aggressively apply it), and dispersants. In cavitation, surfactants aid in evenly dispersing the energy of the bubbles allowing more of them to get to the object being cleaned (an attraction-like action). I personally find I get better results using a surfactant (for this very reason). One also needs to be careful what they use as a surfactant. For example, I have read suggestions by some who sell or make USRCMS to use Photoflo as a surfactant. However, Photoflo is kind of like JetDry and neither are really surfactants because they actually raise the surface tension between two liquids. They are used to prevent hard water spots from etching glass(or photos)and such, etc. Not a concern with plastic (PVC). I do not recommend their use for records.

I could not agree more with the idea of a wet pre-clean with a botanical or natural based enzymatic fluid purpose built for record cleaning. I have been preaching this for a very long time. Even before clogging the filters and pumps by putting dirty or heavily soiled records in a cavitation machine, the other risk is within a couple of such records you will be sand-blasting your records because all that stuff gets churned up again in the water and becomes projectiles hitting your records. Just at the basic level, you are using dirty water at that point to try to clean records. Sure, one could change the water at each record, but who is going to do that? Besides all that, cavitation cleaning is more effective if you pre-clean, surfactant or not.

I find it interesting that everyone is dead set against the use of Photo Flo in cleaning records. The MSDS for Photo-Flo 200 is readily available from Kodak (https://intranet.ssp.ulaval.ca/cgpc/fsss/fichiers/Photo-Flo.pdf) and it lists 2 ingredients. First one is propylene glycol and the second is p-tert-octylphenoxy polyethoxyethyl alcohol.

Propylene glycol is also known as Propane-1,2-diol and diol-1-2, 178, propan-diol . Sound familiar? It should as it is what Mr. Kirmuss states is in his surfactant spray. Despite him saying the MSDS for his spray is on his website, I haven't been able to find it and confirm this, however.

Now the second ingredient (p-tert-octylphenoxy polyethoxyethyl) is more commonly known as Triton X-100 (https://en.wikipedia.org/wiki/Triton_X-100), a commonly used surfactant in the record cleaning world, and is commonly used as an anti-fungal agent as well.

I have seen claims by many that Photo-Flo 200 contains a whole slew of other components, but according to this MSDS that is clearly not the case. Perhaps those claims were made on prior versions of this product which may have had a different formula?

In any case, I have been experimenting with using Photo-Flo 200 as a replacement for the Kirmuss surfactant, and I find a 5% solution of Photo-Flo 200 and distilled water works much the same for me. It will foam and form the white suds (toothpaste?) on certain records and after a full cleaning and rinse I see no build up on my stylus. The cleaning ability seems about the same, but of course that is subjective and difficult to quantify.

A 16 0z bottle sells for $7.99. At a 5% solution this will make up about 2.5 gallons of spray! Add in the cost of distilled water and you are looking at roughly 50 cents for 300 ml of spray vs. $80 for the Kirmuss product.

If you to experiment with Photo-Flo I would suggest you start with records you don't care about, thoroughly clean the applicator brush to make sure you aren't seeing results from residual Kirmuss surfactant and a fresh fill of water. After experimenting, again thoroughly clean the brush and the ultrasonic cleaner to prevent cross contamination.

I imagine there will be a very long rebuttal posted by Mr. Kirmuss, and keep in mind I am not trying to discredit his system or character. I just like to experiment and like Michael finding an inexpensive alternative to the Audio Desk rollers, I too am always looking for cost effective alternatives.

Let us know how it works for you!

Here here!

Ah, so that is what the rollers may be for...ok. good as any explanation to me.

Of course you are right Michael. There are lots of good products commercially available, and I have a few I always use on records that I really care about.

I view record cleaning as a bit of a hobby, and as such I do like to experiment with all sorts of methods and fluids, such as the Photo-Flo method described above. As said earlier I do have a 'system' of vacuum cleaning with Mobile Fidelity fluids that I find brings a dramatic increase in clarity and definition to the sound. The various commercial and home made ultrasonic systems can sometimes do better in reducing clicks and surface noise, but I find this combination of cleaning steps excels in creating black backgrounds and other sonic thrills!

It is time consuming as it is a 3 part process, starting with Super Deep Cleaner followed by Plus Enzymatic Cleaner and finally either their Pure rinse water or a suitable lab grade rinse (distilled doesn't cut it, you can hear the difference).

In any and all cases, however, cleaning records by any of the accepted commercially available systems yields significant improvements, from the humble Spin Clean all the way up to the Audio Desk.

Nice find!

I think that I, he of twelve left thumbs, could even do that.

These are on my hit list.

__

Regarding cleaning:

I start with a Nitty gritty cleaning, then to the Audio Desk.

Then, I put a sticker on the record cover to remind me that it has been cleaned and, from then on, just carbon brushes in the future.

Be sure to put your sticker on the record inner or outer sleeve, not the cover. It will reduce the value of the record. Even if that doesn't matter to you now, you may change your mind in the future. And once done, it can't be undone.

Good listening,

Z

Now me confused. Don't use the Home Depot rollers?

Apologies for any misunderstanding.

Dang!

So close!

I may ask some of my audio club nerds about this and see what we can do.

Still a great idea!

I suspect there's probably a lot of that going on that's confusing the Home Depot accountants. :-)

I also use PhotoFlo as a surfactant. It works great with a Small amount of Dove detergent in my ultrasonic cleaner.

I was going to guess, looking at the photo, that one was a maki sushi roll, and the other was a rolled up Japanese towel that they gave to you before serving up the sushi. Sorry. My bad.

I tried to post a data-filled scientific explanation of photoflo as a former black and white photographer who developed his own films and prints, along with chemical data. I also figured out where to find the data Mr. Kirmuss speaks of on his site (it is hidden in the FAQs).

However, something went wonky and I got an error when I posted and it put it up three times with just two words as the title.

Sorry, but I don't have time to re-write everything. However, one can google for info as one should anyway. (Just choose the source carefully).

Hey Michael, it sounds like you just need to find a plastic sleeve to fit over the capstan to snug up the fit between the capstan and the inner dimension of the roller, yes? Something like a plastic straw of the right size? Maybe I'll get the rollers and see what I can find that might work as it would be worth it to save the $99 stock item price.

I do recommend washing the rollers with a bit of Dawn dishwashing detergent when they start to look less than a nice white color. Make sure you rinse really well before reinserting in your cleaner. Works for me.

I've just bought ten of these for £6.50 at my local decorators shop and they seem to be available for half that price from China (including postage!). I have drilled a hole in one (and it does rotate a bit wonkily but practice will make perfect, I hope!) and it works without coming loose (so far). Perhaps your hole is too wide : I measured its diameter as 2.7mm with a digital caliper so I drilled with a 2.5mm bit and reamed the top of the hole by hand with a 3mm bit. 1/8" is a little wider than that.

I'm intrigued by your dangling statement, "But there is an issue..". What is the issue?

I've just bought ten of these for £6.50 at my local decorators shop and they seem to be available for half that price from China (including postage!). I have drilled a hole in one (and it does rotate a bit wonkily but practice will make perfect, I hope!) and it works without coming loose (so far). Perhaps your hole is too wide : I measured its diameter as 2.7mm with a digital caliper so I drilled with a 2.5mm bit and reamed the top of the hole by hand with a 3mm bit. 1/8" is a little wider than that.

I'm intrigued by your dangling statement, "But there is an issue..". What is the issue?

If you have a drill press and the right round-over router bit, you might be able to add the ridge yourself to the cheaper rollers. Also, the drill press will help a ton in getting the hole off to the side drilled parallel to the roller. I've never run a router bit in something as slow as a drill press, but I'm sure it's feasible, if you make a sturdy jig to hold the roller, set the press to a slow speed, and don't apply too much pressure at once (take your time).

If I sell my very fancy drill press, I'd get about 1/5 of the way to being able to buy that nice German RCM....

I don't think it's obsessional to want to spend less money! Anyway I have now cleaned about 20 LPs with the "new" cheap rollers and they haven't stopped spinning or risen up off their post. I was joking when I said your hole was too wide but perhaps I'm right. The 2.5mm hole seems to grip the rollers OK with the 3mm widening at the top aiding the shoving down of the roller. You should change from imperial to metric!